Technical features:

Material: Polyolefin, flame-retardant, halogen-free

Shrink rate: 2 : 1

Operating temperature: -55 °C to 125 °C

Shrink temperature: 100 °C

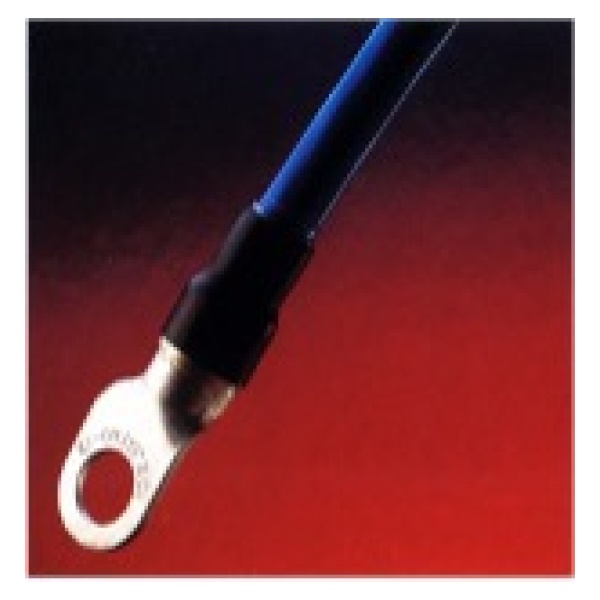

Application: Heat Shrink Tubing with low smoke emission

| Test | Values | |

| Tensile strength | ISO 37 | > 7 MPa |

| Elongation at break | ISO 37 | > 200 % |

| Specific weight | ISO 1183 | < 1,35 |

| Thermal shock | ASTM D2671 (4 h at 175C) | no dripping, cracking or flowing |

| Heat aging | ISO 188 (168 h at 135 °C) | no cracking |

| Flexibility at low temperature | ASTM D2671 (4h at -35°C) | no tearing |

| Flammability | ASTM 876 | passed |

| Dielectric strength | IEC 243-1 | > 15 kV/mm |

| Corrosion resistance (copper level) | ASTM D2671 | no corrosion |

| Water absorption | ISO 62 | < 0.5% |

| Resistance to liquids

> Diesel, Gasoline, Kerosene |

ISO 1817 ISO 37 |

4 MPa > 100% |

| Oxygen index at ambient temperature | ISO 4589-2 | < 32 |

| Smoke index | IEC 60684-2 | < 20 |

| Toxicity index | IEC 60684-2 | < 5 per100 g |

| Resistance to fungi | IEC 68-2-10 | < 2 |

| Approvals | ||

| Military | UL | BS |

| DEF Standard 59-97 | BS4G-198 Pt.3 Type 15 | |

Dimensions

Shrinkage rate 2 : 1

| Item number | min. diameter | max. diameter shrunk | Wall thickness after shrinkage | Length on spool | ||||

| [mm] | [inches] | [mm] | [inches] | [mm] | [inches] | [m] | [inches] | |

| SSPOZHFR3/64″ | 1,2 | 0.023 | 0,6 | 0.023 | 0,40 | 0.016 | 150 | 500 |

| SSPOZHFR1/16″ | 1,6 | 0.031 | 0,8 | 0.031 | 0,43 | 0.017 | 150 | 500 |

| SSPOZHFR3/32″ | 2,4 | 0.046 | 1,2 | 0.046 | 0,51 | 0.020 | 150 | 500 |

| SSPOZHFR1/8″ | 3,2 | 0.062 | 1,6 | 0.062 | 0,51 | 0.020 | 150 | 500 |

| SSPOZHFR3/16″ | 4,8 | 0.093 | 2,4 | 0.093 | 0,51 | 0.020 | 75 | 500 |

| SSPOZHFR1/4″ | 6,4 | 0.125 | 3,2 | 0.125 | 0,64 | 0.025 | 75 | 250 |

| SSPOZHFR3/8″ | 9,5 | 0.187 | 4,8 | 0.187 | 0,64 | 0.025 | 75 | 250 |

| SSPOZHFR1/2″ | 12,7 | 0.250 | 6,4 | 0.250 | 0,64 | 0.029 | 75 | 250 |

| SSPOZHFR3/4″ | 19,1 | 0.375 | 9,5 | 0.375 | 0,76 | 0.030 | 60 | 200 |

| SSPOZHFR1″ | 25,4 | 0.500 | 12,7 | 0.500 | 0,89 | 0.035 | 60 | 200 |

Standard color:

black (bw), other colors on request