Technical Data

Electrical Properties – Nomex® Bolt Insulation

| Property of Base Material | 50μm (2 mil) | 75μm (3 mil) | 125μm (5 mil) | Test Method |

| Dielectric strength (AC Rapid Rise) (V/mil) | 430 | 550 | 680 | ASTM D149* |

| Dielectric constant at 60Hz | 1.6 | 1.6 | 2.4 | ASTM D3426 |

| *Corresponds with IEC 243-1, 9.1m except for electrode set up of 50mm | ||||

Physical Properties – Nomex® Bolt Insulation

| Property of Base Material | 50μm (2 mil) | 75μm (3 mil) | 125μm (5 mil) | Test Method |

| Weight g/m2 | 41 | 63 | 116 | ASTM D646 |

| Density [g/cc] | 0.72 | 0.08 | 0.13 | – |

Mechanical Properties – Nomex® Bolt Insulation

| Property of Base Material | 50μm (2 mil) | 75μm (3 mil) | 125μm (5 mil) | Test Method |

| Tensile Strength (Newtons/cm) | ||||

| Along machine direction (MD) | 39 | 65 | 137 | ASTM D828 |

| Across machine direction (TD) | 18 | 32 | 66 | |

| Elongation Before Failure (%) | ||||

| MD | 9 | 11 | 15 | ASTM D828 |

| TD | 6 | 8 | 12 | |

| Elmendorf Tear (N) | ||||

| MD | 0.8 | 1.2 | 3.4 | TAPP1-414 |

| TD | 1.6 | 2.3 | 5.2 | |

| Initial Tear Strength (Newtons) | ||||

| MD | 11 | 16 | 33 | TAPP1-414 |

| TD | 6 | 8 | 17 | |

| Shrinkage at 300ºC (%) | ||||

| MD | 2.2 | 1.1 | 0.9 | ASTM D1004 |

| TD | 0.1 | 0.0 | 0.0 |

Electrical Properties – Non-Shrink Polyester Bolt Insulation

| Property of Base Film | Typical Value | Test Condition | Test Method |

| Dielectric strength (v) | 6400 | 25ºC, 50Hz and 50mm electrode | ASTM D 149-64 |

| Film thickness (mm) | 0.0254 | 25ºC, 7500v, 150ºC 5000v | – |

| Surface resistivity

ohms per square |

1016 |

25ºC, 30% relative humidity |

ASTM D 257-78 |

Physical Properties – Non-Shrink Polyester Bolt Insulation

| Property of Base Film | Typical Value | Test Condition | Test Method |

| Tensile Mpa (Machine Direction) | 200 | 25ºC | ASTM D 882-80 |

| Elongation % (MD) | 130 | 25ºC | ASTM D 882-80 |

| Stress to produce 5% elongation Mpa (MD) | 105 | 25ºC | ASTM D 882-80 |

| Moisture absorption | less than 8% | 24hrs at 25ºC immersion | ASTM D 570-63 |

Thermal Properties – Non-Shrink Polyester Bolt Insulation

| Property of Base Film | Typical Value | Test Method |

| Melt Point | (526-528K) 253-255°C | ASTM D 3148-82 |

Technical Data

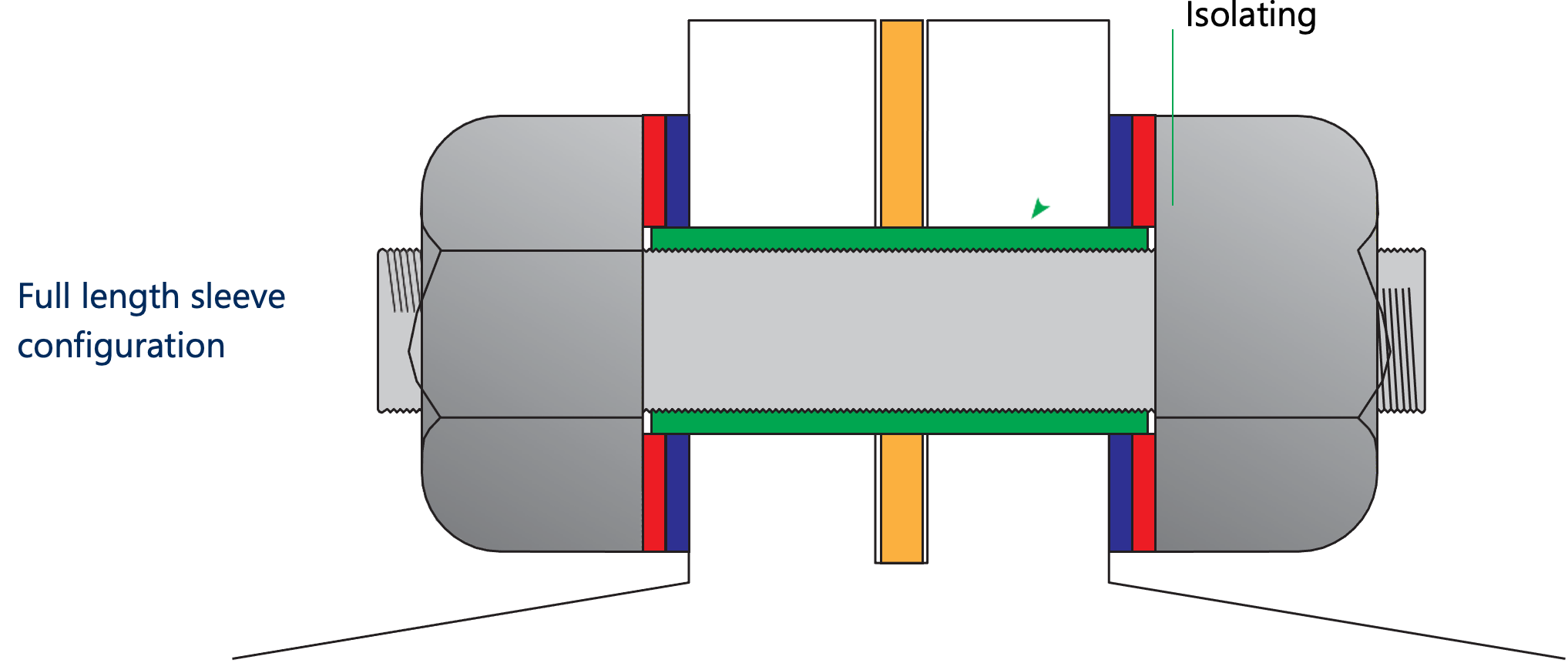

Wall thickness 0.5mm Supplied in standard lengths of 1000mm and 2000mm

|

Bolt Diameter |

Minimum Internal Tube Diameter (mm) | Maximum External Tube Diameter (mm) |

| 8 | 8.25 | 9.51 |

| 10 | 10.25 | 11.51 |

| 12 | 12.25 | 13.51 |

| 14 | 14.25 | 15.51 |

| 16 | 16.25 | 17.51 |

| 18 | 18.25 | 19.51 |

| 20 | 20.25 | 21.51 |

| 22 | 22.25 | 23.51 |

| 24 | 24.25 | 25.51 |

| 26 | 26.25 | 27.51 |

| 27 | 27.25 | 28.51 |

| 30 | 30.50 | 31.76 |

| 33 | 33.50 | 34.76 |

| 36 | 36.50 | 37.76 |

| 39 | 39.50 | 40.76 |

| 42 | 42.50 | 43.76 |

| 45 | 45.50 | 46.76 |

| 48 | 48.75 | 50.01 |

| 52 | 52.75 | 54.21 |

| 56 | 56.75 | 58.21 |

| 60 | 60.75 | 62.21 |

| 64 | 64.75 | 66.21 |

| 68 | 68.75 | 70.21 |

| 72 | 72.75 | 74.21 |

| 76 | 76.75 | 78.21 |

| 80 | 80.75 | 82.21 |

| 84 | 84.75 | 86.21 |

| 88 | 88.75 | 90.21 |

| 92 | 92.75 | 94.21 |

| 96 | 96.75 | 98.21 |

| 100 | 100.75 | 102.21 |