Die-cut parts, adhesive or non-adhesive / Materials and production

The use of insulating molded and die-cut parts results in considerable material and assembly time savings in a number of assembly processes. Die-cut parts are manufactured from all film-type materials according to your specifications – on a roll, as a sheet or as a single part. Aids such as grip tabs or butterfly folding are possible. We die-cut a wide variety of materials in our company.

For example:

- Kapton® HN polyimide films

- Nomex® 410 aramid papers

- Mylar® A polyester films

- Hostaphan® RN polyester films

- Crepe paper adhesive tapes

- PTFE films

- Polycarbonate films

- Self-adhesive glass fabrics

- PPS, PEI, PES or PEEK high-conductivity films

- FEP films

- Acetate silk fabric

- Laminates made from different Products

- and much more

Technical production possibilities:

- Rotary punching machines for large series

- Stroke punching for parts from a few mm² to approx. 0.3m²

- Cutting plotter up to 1.3 x 2.2 m

- Printing units for UV varnish

- Laminating, cutting to length, folding

- 3D die-cut parts, customized die-cut parts

- Wage stamping

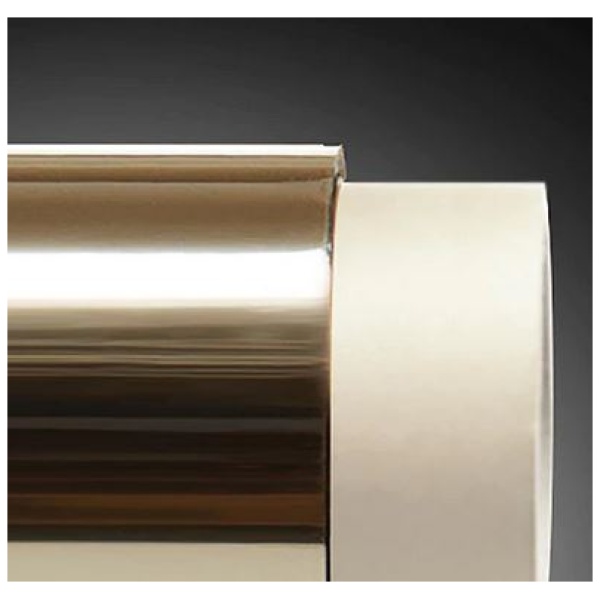

Producing non-adhesive punched parts on rolls

This kind of delivery form of die-cut parts made of non-adhesive materials is particularly suitable for industrial applications because the practical packaging type allows simple and fast further processing.

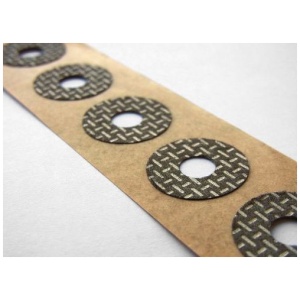

Punched parts for EMC shielding

Most electronic applications have different requirements for electromagnetic shielding. We offer a wide range of EMC shields that are precisely tailored to customer-specific requirements.

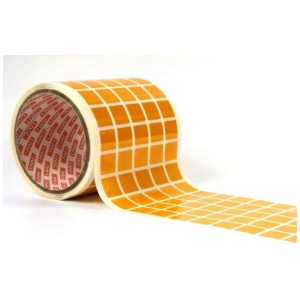

Adhesive die-cut parts made from films

The “Adhesive bonding” processing technique has many advantages compared to other types of fastening. Punched parts made from adhesive tapes (adhesive on one or both sides) are even more practical, as they ensure adhesion without the need for additional tools.

Production methods

Different tools are used for the production of die-cut parts. In most cases, a so-called steel band tool is used. The tool consists of a plywood plate into which steel band knives and punches are inserted. Accuracies of up to +/- 0.2 mm can be achieved and medium quantities of up to approx. 200,000 parts are possible. Full-cut tools are used when a higher number of punched parts is required, greater accuracy is required or, for example, 3D cuts or punching in hard materials are required.

A modern cutting plotter is used for large parts and/or smaller series (prototypes). It can be used to produce parts up to 1.3 m x 2.2 m in size.

The use of pre-formed insulation parts is recommended for series of 100 pieces or more. The user saves on expensive manual production on folding and creasing devices and can be sure that all molded parts have the same dimensions.

Insulating molded parts are manufactured according to the user’s dimensions. We preferably require a echnical drawing in .PDF or .STP format to provide a quotation or for production.

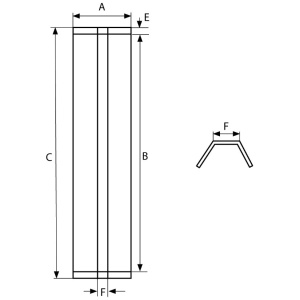

We will be happy to help you determine the correct for Slot insulations, Slot Closures or Intermediate insulations for electric motors. Here you will find a form with the dimensions required for production. Copy the form, fill it in and send it to us.

Dimensional drawings for insulating molded parts for electric motors

|

Groove insulations

Material: …………………………………………………………………………………………

Temp. Class: ……………………………………………………………………………….

Thickness: …………………………………………………………………………………….

Quantity: ………………………………………………………………………………….

Dimensions: A = Overall width: ………………………………………………………….. B = Inside length: ……………………………………………………………… C = Outside length: ……………………………………………………………. D = stretched length: …………………………………………………….. E = Shelf: ………………………………………………………………. F = Rebate (outside): …………………………………………………………….. A x B/C/D ………………………………………………………………. Rebate ………………………………………………………………. Our Art. No. IF…………………………………………………………… Your order no. …………………………………………………………….. |

|

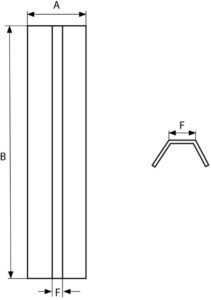

Slot Closures and intermediate insulations

Material: ………………………………………………………………………………………………. Temp. Class: ……………………………………………………………………………………… Thickness: …………………………………………………………………………………………………… Quantity: ……………………………………………………………………………………………….. Dimensions: A = Overall width: ………………………………………………………………. B = Length: ………………………………………………………………. F = Fold (outside): ………………………………………………………………. A x B/ ………………………………………………………………. Fold ………………………………………………………………. Our Art. No. IF……………………………………………………………. Your order no. ………………………………………………………………………………

|