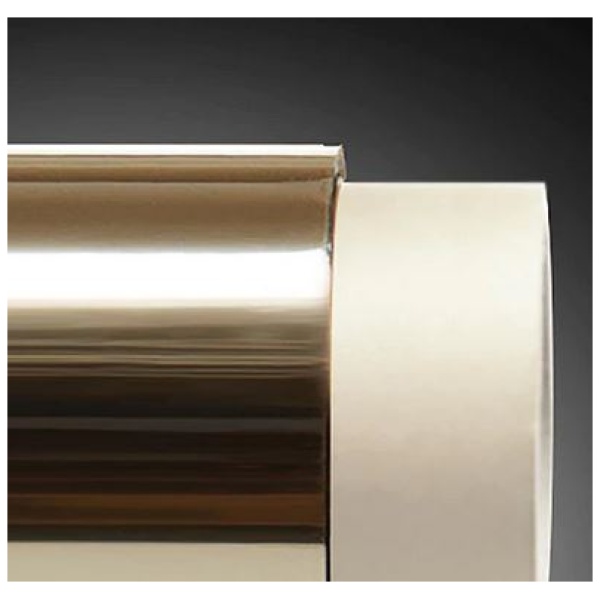

Polyester films Mylar®, Hostaphan®

Properties

Mylar® and Hostaphan® are high-quality polyester films (PET, polyethylene terephthalate) that can be used in electrical insulation systems as voltage-resistant electrical insulation. Due to its excellent dielectric strength, PET film is suitable for use as slot closure and slot insulation.

Material:

Polyethylene terephthalate (PET) Mylar® A slightly cloudy (PFM) Hostaphan® RN slightly cloudy (PFHRN) Hostaphan® WN milky white (PFHWN)

Temperature class:

B (130°C)

Density:

1.395 g/cm3

Thickness dimensions:

0.023 mm – 0.500 mm thickness

Outer diameter approx. 240 mm with standard barrel length

Technical data Mylar® A: ( technical data for Hostaphan® on request )

| Article-No. | Nominal thickness [µm] ±10% | Breakdown voltage [kV] | Grammage [g/m2] | Yield [m2/kg] | Standard running length [m] | |

| PFM023 | * | 23 | 4 | 32 | 31 | 1690 |

| PFM036 | * | 36 | 5,5 | 50 | 20 | 1080 |

| PFM050 | * | 50 | 7,7 | 70 | 14,0 | 780 |

| PFM075 | ♦ | 75 | 10 | 105 | 9,6 | 520 |

| PFM100 | ♦ | 100 | 11,75 | 140 | 7,2 | 390 |

| PFM125 | ♦ | 125 | 13,5 | 175 | 5,7 | 310 |

| PFM190 | ♦ | 190 | 17,7 | 265 | 3,8 | 200 |

| PFM250 | ♦ | 250 | 19 | 350 | 2,9 | 160 |

| PFM300 | ♦ | 300 | 19,5 | 418 | 2,4 | 130 |

| PFM350 | ♦ | 350 | 20 | 480 | 2,1 | 110 |

| PFM500 | ♦ | 500¨ | 32,5 | 670 | 1,5 | 80 |

♦ in wide rolls from stock ♦ no stock item

| Delivery formats: | Standard rolls | 900 – 1230 mm width |

| Narrow rolls | from 4 mm width | |

| Roller diameter | 240 – 250 mm | |

| Feathering | Depth 1- 4 mm/step 0.5 mm | |

| Article-No. | Example: PFM190/022.5 | |

| PFM190 | = Master number | |

| xxx.x | = 022.5 Width 22.5 mm |

Nomex® Aramid paper

Properties:

NOMEX® is a synthetic aromatic polyamide polymer (aramid), which is characterized by a particularly stable molecular structure. This results in the excellent dielectric, thermal, chemical and mechanical properties of NOMEX® and opens up a wide range of applications for NOMEX® Products. NOMEX® paper is manufactured from two forms of the aramid polymer, the fibrids (as binding particles) and the flakes in a paper manufacturing process (type 411). In a second step, the NOMEX® papers (types 410, 414, E56, 418) are highly compacted and cross-linked in a high-temperature calendering process.

| Material | Thicknesses [mm] | ||||||

| NOMEX® type 410 calendered standard version |

|||||||

| NOMEX® type 411 Uncalandered, soft, absorbent variant |

— | — | — | 0,18 | 0,25 | — | 0,38 |

| NOMEX® type 414 Similar to type 410, more flexible, therefore more malleable with a more open surface and better absorbency compared to type 410 |

— | — | —- | 0,18 | 0,25 | 0,30 | 0,38 |

| Material | Thicknesses [mm] | ||||||

| NOMEX® type T993 Medium density, moldable, good absorbencyApplication: Production of winding cores and spacers in transformer construction |

1,0 | 1,5 | 2,0 | 2,4 | 3,0 | 4,0 | — |

| NOMEX® type T994 Highly compacted, mechanically high-strengthApplication: Spacers, strips, spacer rings in transformer construction, soldering pads, Ultrasonically welded strip mats |

4,8 | 5,0 | 6,0 | 6,4 | 7,0 | 8,0 | 9,6 |

Nomex® Aramid paper type 410

Properties:

Nomex® Type 410 has good mechanical toughness, flexibility and resilience and is an ideal surface insulating material, even at high temperatures. Nomex® Type 410 is characterized by a high dielectric strength even without treatment with impregnating agents. Due to its polymer structure, this material can also be used very well at low temperatures (down to -190°C). Nomex® is practically unaffected by most solvents and is highly resistant to acids and alkalis. It is compatible with all types of resins, paints and adhesives as well as transformer fluids, lubricating oils and coolants. Nomex® has good tear and abrasion resistance. Even at considerably higher temperatures than 180°C, this material still exhibits usable values. It is flame-retardant and UL-approved as an insulating material for a temperature range of up to 220°C.

Material:

Nomex® Aramid Paper Type 410 is a calendered electrical insulation paper. It is made of a two-component polyamide polymer.

with UL recognition

Temperature range:

220 °C

Dimensions:

| Article-No. | Nominal thickness | Tensile strength | Elongation | Tear resistance | Tear resistance | Dielectric constant (at 60Hz and 23°C) | Loss factor | Dielectric strength | Weight per unit area | Yield

|

|||||

| [µm] | [N/cm] | [%] | [N] | [N] | [kV/mm] | [g/m2] | [m2/kg] | ||||||||

| lengthwise | transverse | lengthwise | transverse | lengthwise | transverse | lengthwise | transverse | ||||||||

| NO410/05 | * | 50 | 39 | 18 | 9 | 6 | 0,8 | 1,6 | 11 | 6 | 1,6 | 0,004 | 17 | 41 | 24.6 |

| NO410/08 | * | 80 | 65 | 32 | 11 | 8 | 1,2 | 2,3 | 16 | 8 | 1,6 | 0,005 | 22 | 64 | 15.5 |

| NO410/13 | * | 130 | 144 | 68 | 16 | 13 | 2,3 | 5,1 | 32 | 16 | 2,4 | 0,006 | 26 | 115 | 8.7 |

| NO410/18 | * | 180 | 228 | 116 | 19 | 15 | 3,6 | 7,1 | 49 | 25 | 2,7 | 0,006 | 33 | 173 | 5.8 |

| NO410/25 | * | 250 | 306 | 152 | 20 | 16 | 5,1 | 9,9 | 71 | 43 | 2,7 | 0,006 | 32 | 248 | 4.0 |

| NO410/30 | * | 300 | 385 | 203 | 23 | 19 | 6,5 | 12,3 | 93 | 51 | 2,9 | 0,007 | 33 | 309 | 3.2 |

| NO410/38 | * | 380 | 482 | 263 | 21 | 17 | 8,1 | 14,7 | 116 | 71 | 3,2 | 0,007 | 32 | 393 | 2.5 |

| NO410/51 | * | 510 | 657 | 376 | 22 | 17 | 11,5 | 19,6 | 162 | 110 | 3,4 | 0,007 | 31 | 546 | 1.8 |

| NO410/61 | * | 610 | 823 | 534 | 21 | 15 | — | — | 187 | 146 | 3,7 | 0,007 | 32 | 695 | 1.4 |

| NO410/76 | * | 760 | 910 | 613 | 20 | 16 | — | — | 240 | 191 | 3,7 | 0,007 | 27 | 841 | 1.2 |

* no stock item

Delivery formats:

Standard rolls 610 or 914 mm wide

Narrow rolls from 6 mm wide

Item number:

Example: NO410/05/xxx.x NO410/05 = master number xxx.x = 022.5 = width 22.5 mm