Technical features:

Shrinkage rate: 4 : 1

Material: Polytetrafluoroethylene (PTFE) Exelent chemical and temperature resistance

Operating temperature: -67 °C to 250 °C

Shrinkage temperature: > 327 °C

Burning behavior: flame-retardant

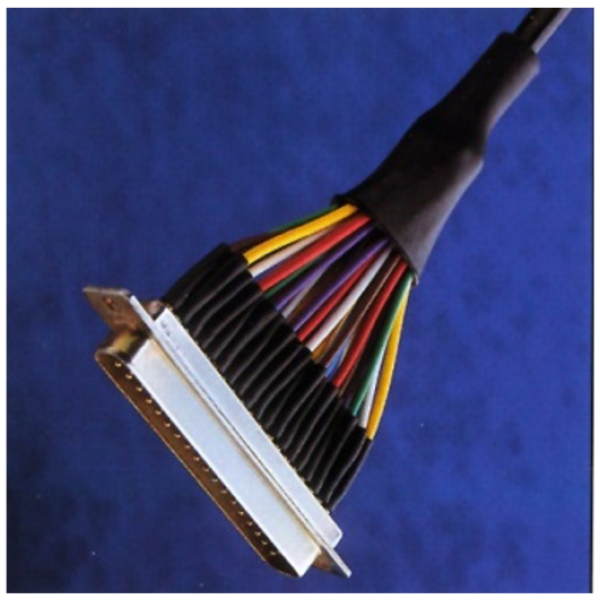

Application: Aviation, medicine

| Test | Values | |

| Tensile strength | ASTM D638 | > 2500 – 4000psi |

| Elongation at break | ASTM D638 | > 225 – 450% |

| Flexibility at low temperature | MIL-1-23053 | no breaking |

| Coefficient of friction | 0,10 | |

| Dielectric strength | ASTM D876 | > 14 kV/mm |

| Dielectric constant | ASTM D150 | 2,05 ± 0,05 |

| Insulation resistance | ASTM D876 | 1018 W/cm |

| Corrosion resistance (copper contact) | MIL-1-23053 | no corrosion |

| Flammability | ASTM D876 | non-flammable |

| Water absorption | ASTM D570 | < 0,01% |

| Resistance to liquids | MIL-1-23053 | No change in properties |

Dimensions

| Item number | min. diameter |

max. Diameter shrunk |

Wall thickness after shrinkage | length |

| [mm] | [mm] | [mm] | [m] | |

| SSPTFE5/64″ | 1,98 | 0,63 | 0,23 | 1,2 |

| SSPTFE1/8″ | 3,17 | 0,94 | 0,25 | 1,2 |

| SSPTFE3/16″ | 4,75 | 1,27 | 0,30 | 1,2 |

| SSPTFE1/4″ | 6,35 | 1,60 | 0,30 | 1,2 |

| SSPTFE3/8″ | 9,52 | 2,44 | 0,30 | 1,2 |

| SSPTFE1/2″ | 12,70 | 3,66 | 0,38 | 1,2 |

| SSPTFE5/8″ | 15,87 | 4,52 | 0,38 | 1,2 |

| SSPTFE3/4″ | 19,05 | 5,69 | 0,38 | 1,2 |

| SSPTFE1″ | 25,40 | 7,06 | 0,38 | 1,2 |

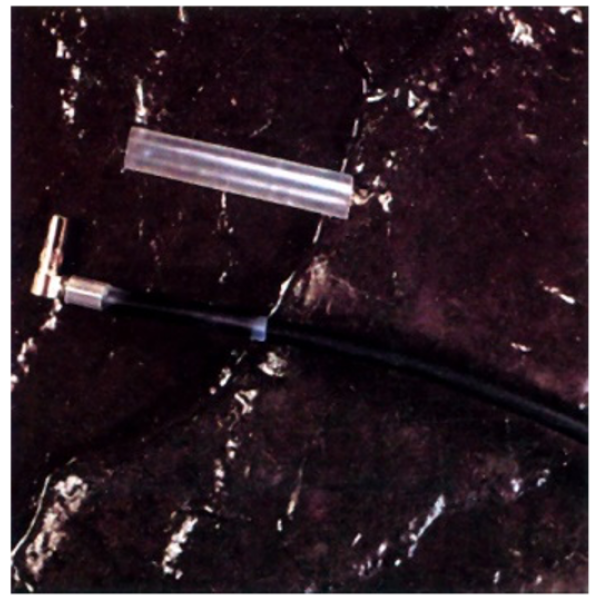

Standard color:

transparent (tr)

other colors on request

Article number:

Example: SSPTFE5/64 “TR

SSPTFE5/64” = master number

TR = transparent color