Technical features:

Material: Polyolefin, flame-retardant, halogen-free

Shrink rate: 3 : 1

Operating temperature: -55 °C to 135 °C

Shrink temperature: 100 °C

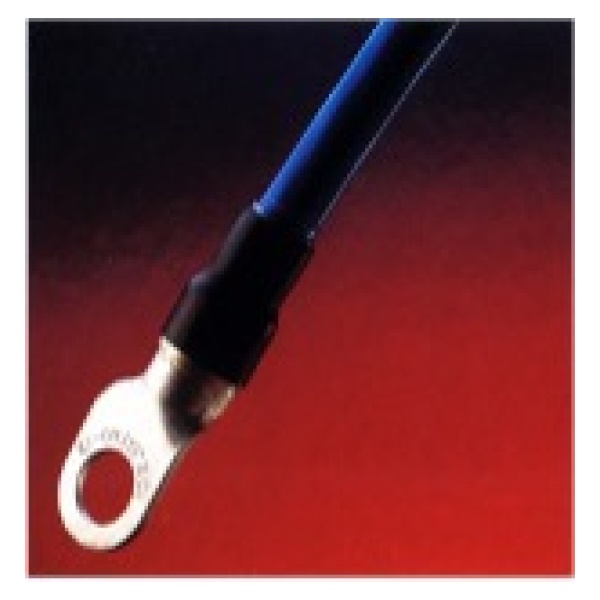

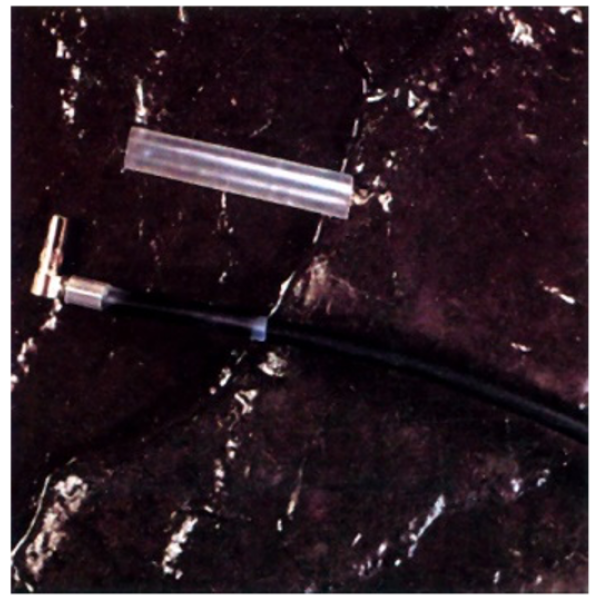

Application: Flat shrink tubing for wrapping flat cables, e.g. connections to printers

| Test | Values | |

| Tensile strength | ISO 37 | > 10 MPa |

| Elongation at break | ISO 37 | > 250% |

| Specific weight | ISO 1183 | < 1,35 |

| Thermal shock | ASTM D2671 (4 h at 250°C) | no dripping, cracking or flowing |

| Heat ageing | ISO 188 (168 h at 175 °C) | no dripping, cracking or flowing |

| Flexibility at low temperature | ASTM D2671 (4h at -55°C) | no cracking |

| Flammability | ASTM 876 | passed |

| Dielectric strength | IEC 243-1 | > 20 kV/mm |

| Corrosion resistance (copper level) | ASTM D2671 | no corrosion |

| Water absorption | ISO 62 | < 0.5% |

Resistance to liquids

|

ISO 1817 ISO 37 |

|

| after testing for resistance to fungi

Tensile strength |

ISO 846 |

|

Dimensions

Shrinkage rate 3 : 1

| Master number | min. diameter | max. diameter shrunk | Wall thickness after shrinkage | Length on spool |

| [mm] | [mm] | [mm] | [m] | |

| SSPO3ZHFR3/32″ | 2,4 | 0,8 | 0,57 | 30 |

| SSPO3ZHFR1/8″ | 3,2 | 1,0 | 0,57 | 30 |

| SSPO3ZHFR3/16″ | 4,8 | 1,6 | 0,57 | 30 |

| SSPO3ZHFR1/4″ | 6,4 | 2,1 | 0,58 | 30 |

| SSPO3ZHFR3/8″” | 9,5 | 3,2 | 0,60 | 30 |

| SSPO3ZHFR12.7 | 12,7 | 4,2 | 0,60 | 30 |

| SSPO3ZHFR3/4″ | 19,0 | 6,4 | 0,60 | 30 |

| SSPO3ZHFR1″ | 25,4 | 8,5 | 0,65 | 30 |

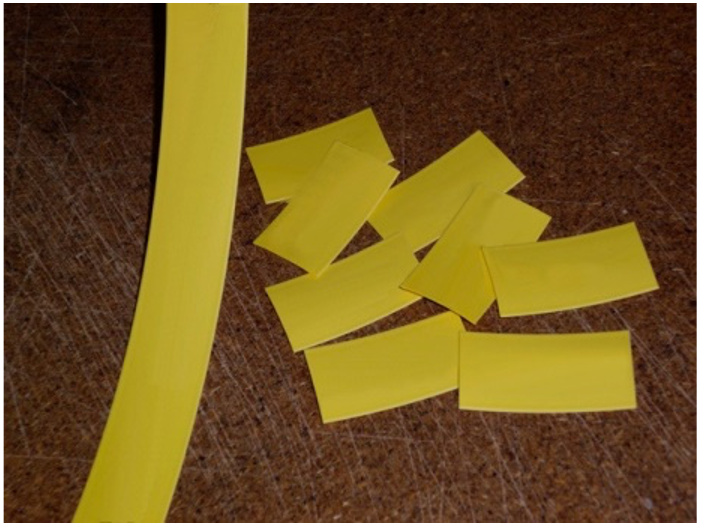

Standard colors:

white (ws), yellow(ge)

Article number:

Example: SSPO3ZHFR3/32 “WS

SSPO3ZHFR3/32” = master number

WS = color white