Specifications

- Low coefficients of friction

- High resistance and hardness values

- Applications at extremely high temperatures

- High compressive strength values

- Extremely long product life cycles and correspondingly low operating costs

Technical data

| Features | Unit | test | extruded | pressed |

| Specific weight | g/cm3 | ASTM D792 | 2,14 -2,18 | |

| Tensile strength | N/mm2 | ASTM D4894 | > 20 | > 24 |

| Tear elongation | % | ASTM D4894 | > 200 | > 250 |

| Compressive strength at 1% deformation | N/mm2 | ASTM D695 | 4 -5 | |

| Coefficient of friction | – | ASTM D1894 | 0,06 | |

| Operating temperature range | °C | — | – 200 to + 260 | |

| dielectric strength | kV/mm | ASTM D149 | > 20 | > 40 |

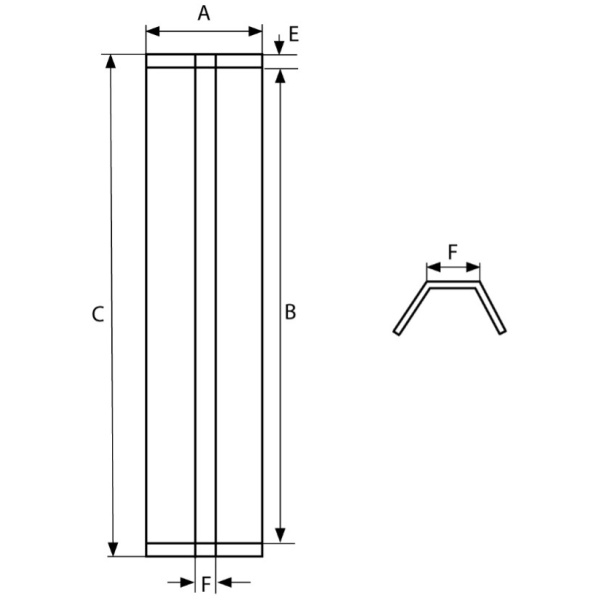

Dimensions:

| Master number | Thickness [mm] | Tolerance[mm] | Size [mm] | Tolerance [mm] | |

| PTFE0500 | ♦ | 0,50 | +0,03 – 0 | ||

| PTFE1000 | ♦ | 1,00 | +0,05 – 0 | ||

| PTFE1500 | ♦ | 1,50 | +0,10 – 0 | ||

| PTFE2000 | ♦ | 2,00 | +0,20 – 0 | 600 x 600 | +20 – 0 |

| PTFE2500 | ♦ | 2,50 | +0,25 – 0 | 1000 x 1000 | +30 – 0 |

| PTFE3000 | ♦ | 3,00 | +0,30 – 0 | 1200 x 1200 | +40 – 0 |

| PTFE4000 | ♦ | 4,00 | +0,40 – 0 | 1500 x 1500 | +40 – 0 |

| PTFE5000 | ♦ | 5,00 | +0,50 – 0 | ||

| PTFE6000 | ♦ | 6,00 | +0,60 – 0 | ||

♦ Available from factory stock

Item number:

Example: PTFE0500/xxxx/yyyy

PTFE0500 = master number

xxxx = length

yyyy = width