Types K and E with ceramic insulation KD500

These thermal and compensating conductors are made of two ceramic-coated wires. Their outstanding features are:

- Extremely high temperature resistance

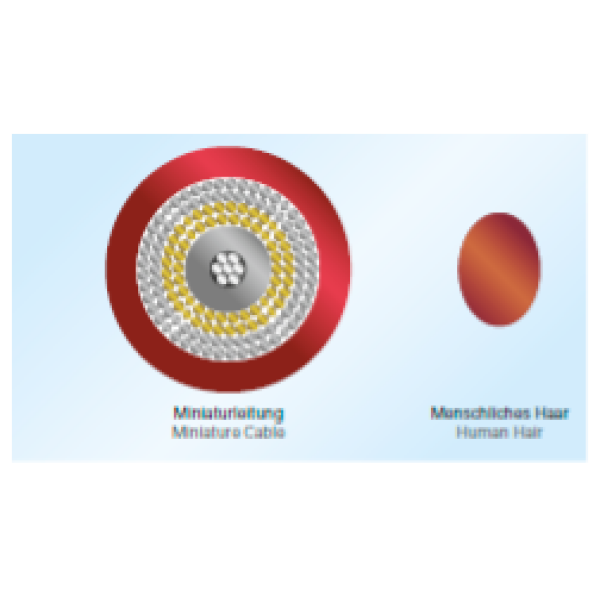

- Miniaturized sizes

- Greatly reduced weight

Properties

Thermal:

Continuous temperature -90°C to +500°C, 800°C for at least 240h Peak temperature 1000°C Nickel migration.

From temperatures of >315°C, the cables may be subject to nickel migration after prolonged use and thus experience an increase in maximum resistance.

Chemical:

Excellent resistance in chemical environments (standard and organic solvents). Poor resistance to moisture.

Electrical:

Test voltage (1 min) 150V AC / 212V DC

Radiation resistance:

Can be exposed to neutrons or gamma rays for long periods without changing the mechanical resistance of the insulation.

Flame resistance:

Completely incombustible. Above >1000°C the wires can melt but not burn.

Color:

Grey

Outgassing:

Low

Halogen-free:

Yes

Dimensions

| Type | Number x conductor diameter | AWG | Nominal diameter |

Weight g/km |

Length m/kg |

| Type K | 2 x 0.20 mm | 2 x AWG 32 | 0.44 mm | 286 | 3500 |

| Type K | 2 x 0.32 mm | 2 x AWG28 | 0.68 mm | 637 | 1570 |

| Type K | 2 x 0.50 mm | 2 x AWG 24 | 1.04 mm | 1754 | 570 |

| Type E | 2 x 0.20 mm | 2 x AWG 32 | 0.44 mm | 286 | 3500 |

| Type E | 2 x 0.30 mm | 2 x AWG 28 | 0.68 mm | 637 | 1570 |

Other types on request.

EMK type K

| Temperature | EMF | Tolerance | |

| Class 1 (KX1) | Class 2 (KX2) | ||

| 0°C | 0 µV | ±60 µV | ±100 µV |

| 100°C | 4.095 µV | ±60 µV | ±100 µV |

| 200°C | 8.137 µV | ±60 µV | ±100 µV |

| 400°C | 16.395 µV | ±60 µV | ±100 µV |

EMK type E

| Temperature | EMF | Tolerance | |

| Class 1 (KX1) | Class 2 (KX2) | ||

| 0°C | 0 µV | ±120 µV | ±200 µV |

| 100°C | 6.319 µV | ±120 µV | ±200 µV |

| 200°C | 13.421 µV | ±120 µV | ±200 µV |

| 400°C | 28.946 µV | ±120 µV | ±200 µV |

Processing instructions

Ceramic is very different from conventional wire insulation. It is very hard and sensitive to moisture. It therefore requires special care during processing:

- The wires must be stored and processed in a dry environment.

- The wires must not be subjected to impact or shock.

- The wires must not be kinked under any circumstances. Visual inspection: A bending radius that is too tight or a kink in the wire can generally be recognized by cracks in the ceramic insulation, which are visible as bleaching of the surface.

Advise for the stripping of the insulation

The ceramic coating on the KD500 is very thin and adheres to the conductor. Conventional stripping tools can therefore not be used. Stripping can be carried out with fine sandpaper.