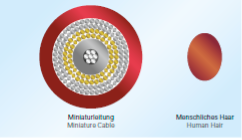

Micro cables

Our supply plant develops and produces application-specific cables with cross-sections up to AWG 56 and coaxial cables up to AWG 46. What is barely visible to the eye is nevertheless absolutely impressive: important functions such as low-noise and highly flexible cable designs are ensured by the use of high-performance materials and special alloys Special shielding guarantees optimum EMC properties. Features such as application-optimized haptics, sterilizability/autoclavability and biocompatibility in accordance with ISO 10993 are guaranteed by the use of state-of-the-art materials. Outstanding areas of use include highly sensitive applications such as minimally invasive surgical techniques and other innovations in medicine and sensor technology. A few examples: An electronic scalpel allows the surgeon to cut tissue in a targeted manner and simultaneously stop any bleeding that occurs. SpO2 sensors can be used to measure oxygen saturation in the blood. Individual micro cable solutions are also a key element in imaging procedures such as magnetic resonance imaging (MRI) or (video) endoscopy. Here and in many other sensitive applications, the quality of these micro products gives users the reassuring feeling of maximum reliability and safety.

Cables for medical technology

The highly sensitive applications in medical technology place special demands on the cable design. The requirements for these cables are: easy handling, autoclavability and reliability.

Cable design, material and production guarantee maximum mechanical flexibility, extreme tensile strength and small size. High-performance materials, special alloys and patented manufacturing techniques also guarantee biocompatibility in accordance with DIN EN ISO 10993 and are used in the following applications, among others:

- Autoclaves

- Defibrillators

- Dental technology

- ECG and EEG devices

- Endoscopy

| Properties of the insulating materials used | ||||||||

| Fluoropolymers | Elastomers | Thermoplastic elastomers | ||||||

| ETFE | FEP | MFA | PFA | PTFE | Silicone | PUR | Santoprene™ | |

| Continuous operating temperature (20,000 h) | -100 °C

+150 °C |

-100 °C

+200 °C |

-100 °C

+230 °C |

-190 °C

+250 °C |

-190 °C

+260 °C |

– 50 °C

+180 °C |

– 50 °C

+90 °C |

– 50 °C

+ 105 °C |

| Properties of the insulating materials used | ||||||||

| Fluoropolymers | Elastomers | Thermoplastic elastomers | ||||||

| ETFE | FEP | MFA | PFA | PTFE | Silicone | PUR | Santoprene™ | |

| Continuous operating temperature (20,000 h) | -100 °C

+150 °C |

-100 °C

+200 °C |

-100 °C

+230 °C |

-190 °C

+250 °C |

-190 °C

+260 °C |

– 50 °C

+180 °C |

– 50 °C

+90 °C |

– 50 °C

+ 105 °C |

| Biocompatibility | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

| Resistance to disinfectants | ++ | ++ | ++ | ++ | ++ | ++ | + | + |

| Halogen-free | x | x | x | x | x | ✔ | ✔ | ✔ |

| RoHS-compliant | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

| REACH-compliant | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

Santoprene™ is a registered trademark of Exxon Mobil Corporation

Conductor dimensions

| diameter | Cross section | |||

| AWG | min. (mm) | nom. (mm) | max. (mm) | mm2 |

| 40 | 0,076 | 0,079 | 0,081 | 0,0049017 |

| 42 | 0,061 | 0,064 | 0,066 | 0,0032170 |

| 44 | 0,048 | 0,051 | 0,053 | 0,0020428 |

| 46 | 0,0384 | 0,0399 | 0,0417 | 0,0012504 |

| 48 | 0,0302 | 0,0315 | 0,0328 | 0,0007793 |

| 50 | 0,0241 | 0,0251 | 0,0262 | 0,0004948 |

| 51 | 0,0216 | 0,0224 | 0,0234 | 0,0003941 |

| 52 | 0,0191 | 0,0198 | 0,0206 | 0,0003079 |

| 53 | 0,0170 | 0,0178 | 0,0185 | 0,0002488 |

| 54 | 0,0152 | 0,0157 | 0,0165 | 0,0001936 |

| 55 | 0,0135 | 0,0140 | 0,0145 | 0,0001539 |

| 56 | 0,0119 | 0,0124 | 0,0130 | 0.0001208 |

Microminiature coaxial cable

The microminiature coaxial cables are constructed with a solid or foamed fluoroplastic dielectric and are particularly suitable for sensors, measurement technology and medical technology.

| Item number | AWG | Stranded wire: Number of wires/AWG | Diameter dielectric [mm] | Shielding AWG | Type of shielding | Outer Ø

[mm] |

Capacity C

[pF/m] |

| Coaxial cable 50 Ohm with PFA fixed | |||||||

| KOPFA5042U | 42 | 7/50 | 0,15 | 44 | braided | 0,51 | 143,6 |

| KOPFA5040U | 40 | 7/48 | 0,20 | 44 | braided | 0,56 | 122,6 |

| KOPFA5038U | 38 | 7/46 | 0,27 | 44 | braided | 0,64 | 120,3 |

| KOPFA5038G | 38 | 7/46 | 0,22 | 44 | braided | 0,69 | 113,8 |

| KOPFA5036U | 36 | 7/44 | 0,35 | 44 | braided | 0,71 | 120,0 |

| KOPFA5036G | 36 | 7/44 | 0,33 | 44 | braided | 0,79 | 105,2 |

| KOPFA5034U | 34 | 7/42 | 0,45 | 44 | braided | 0,81 | 114,3 |

| KOPFA5034G | 34 | 7/42 | 0,45 | 44 | braided | 0,91 | 100,6 |

| Coaxial cable 75 Ohm with PFA fixed | |||||||

| KOPFA7542U | 42 | 7/50 | 0,28 | 44 | braided | 0,69 | 81,0 |

| KOPFA7542G | 42 | 7/50 | 0,20 | 44 | braided | 0,71 | 80,3 |

| KOPFA7540U | 40 | 7/48 | 0,38 | 44 | braided | 0,79 | 74,0 |

| KOPFA7540G | 40 | 7/48 | 0,33 | 44 | braided | 0,84 | 72,1 |

| KOPFA7538U | 38 | 7/46 | 0,46 | 44 | braided | 0,87 | 77,2 |

| KOPFA7538G | 38 | 7/46 | 0,48 | 44 | braided | 0,99 | 68,4 |

| KOPFA7536U | 36 | 7/44 | 0,68 | 44 | braided | 1,09 | 69,9 |

| KOPFA7536G | 36 | 7/44 | 0,66 | 44 | braided | 1,17 | 67,5 |

| KOPFA7534U | 34 | 7/42 | 0,89 | 44 | braided | 1,29 | 68,5 |

| KOPFA7534G | 34 | 7/42 | 0,89 | 44 | braided | 1,40 | 65,7 |

| Coaxial cable 50 Ohm with PFA fixed | |||||||

| KOPFA5032U | 32 | 19/44 | 0,68 | 40 | braided | 1,19 | 105,0 |

| KOPFA5032G | 32 | 19/44 | 0,68 | 40 | braided | 1,29 | 100,0 |

| KOPFA5030U | 30 | 19/42 | 0,79 | 40 | braided | 1,29 | 110,0 |

| KOPFA5030G | 30 | 19/42 | 0,79 | 40 | braided | 1,45 | 98,4 |

| KOPFA5028U | 28 | 19/40 | 1,02 | 40 | braided | 1,52 | 106,2 |

| KOPFA5028G | 28 | 19/40 | 1,02 | 40 | braided | 1,68 | 98,4 |

| KOPFA5026U | 26 | 19/38 | 1,30 | 40 | braided | 1,80 | 107,2 |

| KOPFA5026G | 26 | 19/36 | 1,35 | 40 | braided | 2,01 | 97,0 |

| KOPFA5024U | 24 | 19/36 | 1,60 | 40 | braided | 2,11 | 110,0 |

| KOPFA5024G | 24 | 19/36 | 1,73 | 40 | braided | 2,39 | 97,2 |

All coaxial cables are specified and tested at 10 MHz and for capacitance at 1 kHz. These coaxial cables can also be manufactured from various combinations of conductor material, dielectric and outer insulation according to customer requirements.

|

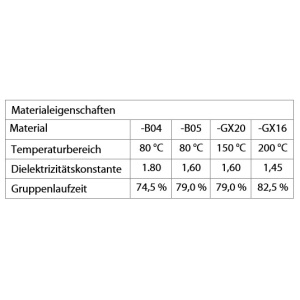

Properties of foamed dielectrics Foamed dielectrics trap a lot of air bubbles and their behavior is therefore similar to that of air dielectrics, whose group delay almost corresponds to the speed of light. |

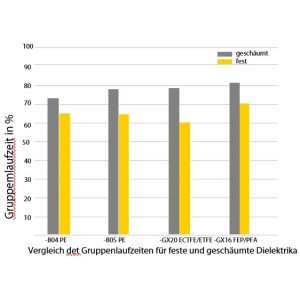

Comparison of the group delay times for solid and foamed dielectrics |

|