Technical features:

Shrink rate: 2 : 1

Operating temperature: -40 °C to 125 °C

Shrink temperature: > 80 °C

Burning behavior: flame-retardant

Application: for heat-sensitive components

| Test | Values | |

| Tensile strength | ISO 37 | >10 MPa |

| Elongation at break | ISO 37 | > 200% |

| Thermal shock | ASTM D2671 (4 h at 200°C) | no dripping, breaking or flowing |

| Heat aging Elongation at break | ISO 188 (168 h at 200 ˚C) / ISO 37 | > 150% |

| Shrinkage rate at 80°C | > 50% | |

| Flexibility at low temperatures | ASTM D2671 (4 h at -45°C) | no breaking |

| Flammability (exception transparent) | MVSS 302 | passed |

| Dielectric strength | IEC 243-1 | > 15kV/mm |

| Corrosion (copper mirror) | ASTM D2671 | no corrosion |

Resistance to liquids

|

ISO 1817 ISO37 |

>5 MPa> 175% |

Dimensions:

| Master number | min. diameter | max. diameter shrunk | Wall thickness after shrinkage | Roll length [m] | |||

| [mm] | [inches] | [mm] | [inches] | [mm] | [inches] | ||

| SSPONT3/64″ | 1,2 | 0.046 | 0,6 | 0.023 | 0,33 | 0.018 | 150 |

| SSPONT1/16″ | 1,6 | 0.063 | 0,8 | 0.031 | 0,36 | 0.018 | 150 |

| SSPONT3/32″ | 2,4 | 0.093 | 1,2 | 0.046 | 0,44 | 0.019 | 150 |

| SSPONT1/8″ | 3,2 | 0.125 | 1,6 | 0.062 | 0,44 | 0.019 | 150 |

| SSPONT3/16″ | 4,8 | 0.187 | 2,4 | 0.093 | 0,44 | 0.026 | 150 |

| SSPONT1/4″ | 6,4 | 0.250 | 3,2 | 0.125 | 0,56 | 0.026 | 75 |

| SSPONT3/8″ | 9,5 | 0.375 | 4,8 | 0.187 | 0,56 | 0.026 | 75 |

| SSPONT1/2″ | 12,7 | 0.500 | 6,4 | 0.250 | 0,56 | 0.029 | 75 |

| SSPONT3/4″ | 19,0 | 0.750 | 9,5 | 0.375 | 0,69 | 0.035 | 60 |

| SSPONT1″ | 25,4 | 1.000 | 12,7 | 0.500 | 0,77 | 0.039 | 60 |

| SSPONT1-1/2″ | 38,1 | 1.500 | 19,0 | 0.750 | 1,00 | 0.039 | 30 |

| SSPONT2 | 50,8 | 2.000 | 25,4 | 1.000 | 1,15 | 0.045 | 30 |

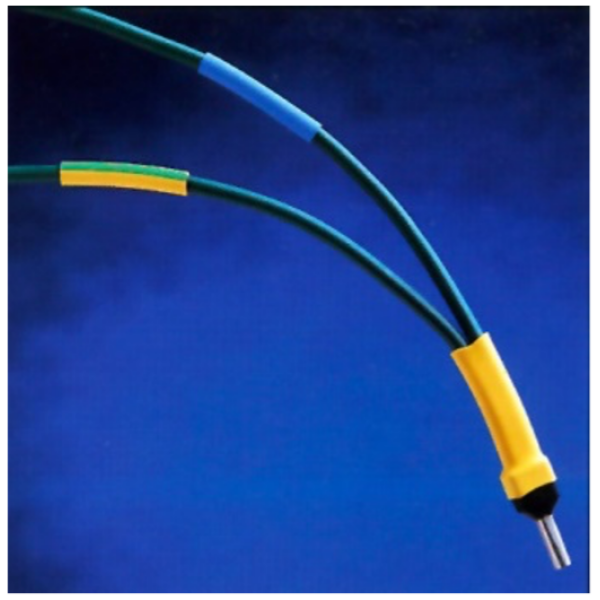

Colors:

black (sw), transparent (tr), red (rt), yellow (ge), blue (bl), white (ws), other colors on request

Article number:

Example: SSPONT3/64 “SW

SSPONT3/64” = master number

SW = color black