Applications:

Special windings for transformers, chokes, coils or sensors that have to function continuously in the low-voltage range at elevated temperatures of up to 500°C (peaks up to 1000°C). Various safety applications that have to withstand a fire of up to 600°C without destruction (mechanical heating, short circuit, heat risks, etc.).

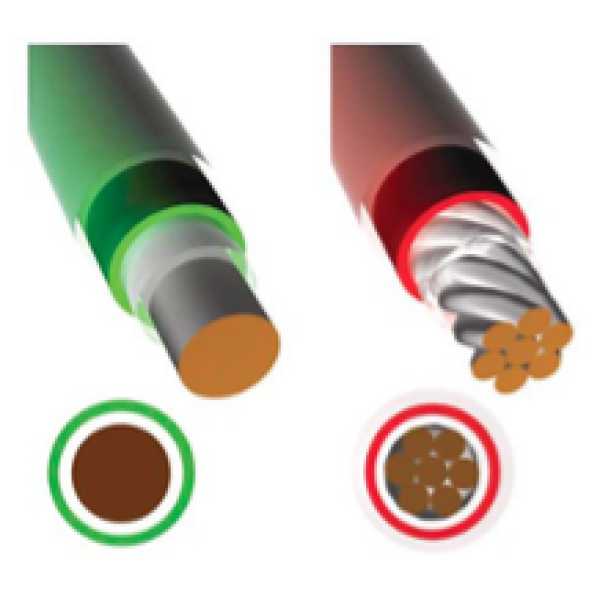

Structure:

| Conductor: | Copper/nickel plating 27% |

| Other conductor materials on request. Special conductor materials provided by the customer can also be processed. Corresponding tests are carried out in the factory | |

| Insulation: | Ceramic in thicknesses of 5-20 µm |

| Color: | gray |

| Dimensions: | AWG 41 to AWG 18 or 0.07 mm to 1.0 mm |

| Linear density: | Like that of copper = 8.92 kg/dm3 per km |

| Nickel migration: | At temperatures >315°C, the KD500 is subject to nickel penetration into the copper. This effect is negligible with larger diameters but considerable with wire diameters <0.15 mm (AWG 34) after an operating time of 48 hours with the consequence of an increase in resistance. |

Heat resistance:

Permanent -90°C to +500°C (2500 hours min.) Short-term up to 800°C (tested for 10 days or 240 hours) and peaks up to 1000°C.

Electrical values:

Test voltage 150V AC, corresponding to 212V DC, test with rolled wire Bending radius = 20 x diameter. For bending radius < 20 x diameter please enquire Breakdown voltage >150V AC Resistance max. 3.10-6 Ω.cm at 20° C after ageing at 500°C

Further properties

| Moisture resistance | The ceramic is sensitive to moisture. It may need to be impregnated in the finished state. |

| Chemical resistance: | The ceramic is highly resistant to solvents and organic oils |

| Radiation resistance | High Resistance. |

| Flammability: | Non-flammable. At temperatures >1000°C the wire can melt but not burn. |

| Bending radius: | 5x outer diameter (see table) |

| Halogen-free: | Yes |

| Outgassing: | None |

Processing instructions

Ceramic is very different from conventional wire insulations. It is very hard and sensitive to moisture. It therefore requires special care during processing.

- KD 500 must be stored and processed in a dry environment.

- The winding must not be subjected to shocks or impacts.

- No higher tensile forces than those specified in the table below may be used for winding.

- The bending radius must not exceed 5 x the outer diameter of the wire (see table).

- The wire should not be unwound overhead but axially, preferably with a constant tensile force.

- The wires must not be kinked under any circumstances. Visually check the winding.

- A bending radius that is too tight or a kink in the wire can generally be recognized by cracks in the ceramic insulation, which become visible as a white discoloration of the surface.

Stripping of Insulation

The ceramic coating on the KD500 is very thin and adheres to the conductor. Conventional stripping tools can therefore not be used. Stripping can be carried out with fine sandpaper.

Please note:

When mechanically stripping nickel-coated wires, this coating must not be removed, otherwise good welding is no longer guaranteed.

Connecting

The ceramic wires are connected either by soldering with silver solder, crimping or wrapping.

Dimensions:

| Item number | Diameter [mm] | AWG Size | Outside diameter [mm] | Weight [g/km] | Length [m kg] |

| KD500/007RR | 0,07 | 41 | 0,086 | 34 | 29 800 |

| KD500/010RR | 0,10 | 38 | 0,116 | 71 | 14 000 |

| KD500/012RR | 0,12 | 36 | 0,136 | 101 | 9 901 |

| KD500/015RR | 0,15 | 34 | 0,167 | 161 | 6 210 |

| KD500/017RR | 0,17 | 33 | 0,186 | 202 | 4 950 |

| KD500/020RR | 0,20 | 32 | 0,217 | 286 | 3 500 |

| KD500/025RR | 0,25 | 30 | 0,268 | 446 | 2 240 |

| KD500/030RR | 0,30 | 28 | 0,318 | 637 | 1 570 |

| KD500/035RR | 0,35 | 27 | 0,368 | 862 | 1 160 |

| KD500/040RR | 0,40 | 26 | 0,418 | 1 136 | 880 |

| KD500/045RR | 0,45 | 25 | 0,468 | 1 433 | 698 |

| KD500/050RR | 0,50 | 24 | 0,518 | 1 754 | 570 |

| KD500/055RR | 0,55 | 23 | 0,568 | 2 105 | 475 |

| KD500/060RR | 0,60 | 22 | 0,619 | 2 500 | 400 |

| KD500/065RR | 0,65 | 22 | 0,669 | 2 899 | 345 |

| KD500/070RR | 0,70 | 21 | 0,719 | 3 356 | 298 |

| KD500/075RR | 0,75 | 20 | 0,769 | 3 846 | 260 |

| KD500/080RR | 0,80 | 20 | 0,820 | 4 348 | 230 |

| KD500/090RR | 0,90 | 19 | 0,920 | 5 814 | 172 |

| KD500/100RR | 1,00 | 18 | 1,020 | 7 194 | 139 |

| Diameter [mm] | Max. permissible tensile force (N) | Minim. Bending radius [mm] | Resistance at 20°C [Ω/m] |

| 7/100 | 0,23 | 0,45 | 7,795 |

| 10/100 | 0,47 | 0,60 | 3,818 |

| 12/100 | 0,67 | 0,70 | 2,652 |

| 15/100 | 1,06 | 0,85 | 1,697 |

| 17/100 | 1,36 | 0,93 | 1,322 |

| 20/100 | 1,88 | 1,10 | 0,954 |

| 25/100 | 2,95 | 1,35 | 0,611 |

| 30/100 | 4,24 | 1,60 | 0,424 |

| 35/100 | 5,77 | 1,85 | 0,312 |

| 40/100 | 7,54 | 2,10 | 0,239 |

| 45/100 | 9,55 | 2,35 | 0,189 |

| 50/100 | 11,78 | 2,60 | 0,153 |

| 55/100 | 14,25 | 2,85 | 0,126 |

| 60/100 | 16,96 | 3,10 | 0,106 |

| 65/100 | 19,91 | 3,35 | 0,090 |

| 70/100 | 23,09 | 3,60 | 0,078 |

| 75/100 | 26,51 | 3,85 | 0,068 |

| 80/100 | 30,16 | 4,10 | 0,059 |

| 90/100 | 38,17 | 4,60 | 0,047 |

| 100/100 | 47,12 | 5,10 | 0,038 |