Applications

Industrial Grade

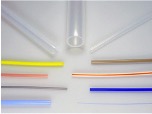

For industrial applications (automotive industry, electronics and electrical engineering, chemical industry, aerospace and aviation, fiber optics, environment and analysis).

Medical Grade

For applications in medical technology (manufacture of medical devices and machines) with certified polymers USP class

Properties

PTFE Polytetrafluoroethylene

The unique properties of PTFE have made it the polymer of choice for many applications. PTFE is used in many products, such as advanced medical devices and high-temperature industrial equipment, due to its low coefficient of friction for a polymer and extremely wide operating temperature range. Unrivaled chemical resistance and extreme chemical inertness have made PTFE the first choice among plastics for the chemical and analytical industries.

FEP Fluoroethylene propylene

Although FEP is similar to PTFE in its properties, it also has some significant differences. It has a slightly higher coefficient of friction, a lower continuous operating temperature and is more transparent than PTFE. FEP also offers lower gas and vapor permeability and excellent UV resistance

PFA Perfluoroalkoxy

PFA was developed to increase the continuous operating temperature of FEP resin. Melt processability allows PFA to be processed in longer continuous lengths than PTFE.

PVDF Polyvinylidene fluoride

PVDF is often referred to by one of its trade names, Kynar®. It was primarily developed for applications that required excellent chemical resistance, high purity levels and superior mechanical properties. PVDF is often used as a lining or protective barrier in chemical applications.

THV Tetrafluoroethylene Hexafluoropropylene Vinylidene Fluoride

THV offers high chemical resistance, high flexibility, low application temperatures and excellent transparency. THV can be radiation cross-linked using an e-beam and can be used in multilayer constructions. It has outstanding permeation resistance to highly aggressive media and chemicals. THV offers excellent optical clarity and transmission, especially in the UV and visible parts of the solar spectrum. THV is easier to bond to other plastics and elastomers than the other fluoroplastics.

Tolerances

Tubing with extremely tight tolerances in diameter and wall thickness can be produced.

Material properties

| Properties | Standard: Din or ASTM | Unit | PTFE* | FEP* | FEP-HT* | PFA* | ETFE* | PVDF* | ECTFE* |

| Density | 53479 | g/cm3 | 2,14-2,19 | 2,12-2,19 | 2,12-2,17 | 2,12-2,17 | 2,12-2,17 | 1,71-1,78 | 1,67-1,7 |

| Upper continuous operating temperature without load | °C | 260 | 205 | 225 | 240 | 150 | 140 | 150 | |

| Flammability | incombustible | incombustible | incombustible | incombustible | self-extinguishing | flame retardant | self-extinguishing | ||

| Water absorption | 53495 | % | <0,01 | < 0,01 | < 0,03 | < 0,03 | < 0,1 | < 0,02 | < 0,1 |

| Tear strength at 23 °C | 53455 | Mpa | 29-39 | 19 -25 | 19 – 32 | 27 – 32 | 36 -48 | 38 – 50 | 41 – 54 |

| Tensile strength at 150 °C | Mpa | 14-20 | 4-6 | n. b. | 15-21 | 8-12 | 7,5 – 10,5 | 3,5 – 4,5 | |

| Residual strength at 250 °C | Mpa | n. b. | n. a. | n. b. | n. a. | n. a. | n. b. | ||

| Yield strength at 23 °C | 53455 | N/mm2 | 10 | 12 | 12 | 14 | 24 | 46 | 34 |

| Elongation at break at 23 °C | 53455 | % | 200-500 | 250-350 | 200-400 | 300-360 | 200-500 | 20-250 | 200-300 |

| Tensile modulus of elasticity at 23 °C | 53457 | N/mm2 | 400-800 | 350-700 | n. b. | 500-550 | 500-1200 | 800-1800 | 1200-1800 |

| Limit bending stress at 23 °C | 63452 | Mpa | 18-20 | n. b. | 15 | 25-30 | 55 | 50 | |

| Bending modulus of elasticity | 53457 | N/mm2 | 600-800 | 660 – 680 | n. b. | 600 – 700 | 1000 -1500 | 1200 -1400 | 1600 -1800 |

| Ball pressure hardness 132/60 | 53456 | N/mm2 | 25-30 | 23 – 29 | 25 – 30 | 25 – 30 | 34 – 40 | 62 – 68 | 55 – 65 |

| Rockwell hardness R | ASTM D725 | n. b. | 45-55 | 100-115 | 85-95 | ||||

| Shore hardness D | 53505 | 55 – 70 | 55 – 60 | n. b. | 59 | 63 – 75 | 73 – 85 | ||

| Coefficient of friction, dynamic, against steel, dry | 0,05-0,2 | 0,3-0,35 | n. b. | 0,2 – 0,3 | 0,3 – 0,5 | 0,2 – 0,4 | 0,6 – 0,7 | ||

| Melting temperature | ASTM 2116 | °C | 327 | 250-282 | 265-275 | 300-310 | 265-275 | 165-178 | 240-247 |

| Dimensional stability in heat A (18.5) kp/cm3 | 53461 | °C | 50 – 60 | 51 | 71-74 | 80-92 | 76 | 80 – 92 | 76 |

| A (18.5) kp/cm3 | ISO | °C | 130 – 140 | 75 | 130-140 | 70 | 104 | 146 – 150 | 115 |

| Lin. Coefficient of thermal expansion | 1/K*10-5 | 10-16 | 8-14 | 8-16 | 10-16 | 8-12 | 8-12 | 4-8 | |

| Thermal conductivity at 23 °C | 52612 | W/K*m | 0,23 | 0,2 | n. b. | 0,22 | 0,23 | 0,17 | 0,15 |

| Spec, heat at 23 °C | KJ/kg*K | 1,01 | 1,17 | n. b. | 1,09 | 1,95 | 1,38 | n. b. | |

| Oxygen index | % | > 95 | > 95 | >95 | > 95 | > 30 | > 43 | >60 | |

| Dielectric constant | 53483 | ||||||||

| at 103 Hz | 2,0-2,1 | 0 2,10 | 2,00 | 2,06-2,10 | 2,60 | 7,80-9,00 | 2,60 | ||

| at 106 Hz | 2,0-2,10 | 2,10 | 2,00 | 2,06-2,10 | 2,60 | 6,40-7,60 | 2,50 | ||

| Dielectric dissipation factor | 53483 | ||||||||

| at 103 Hz | 0,3 – 0,5 | 2 – 8 | n. b. | 0,20 | 6 -8 | 150 -200 | 30 | ||

| at 106 Hz | 0,7 – 1,0 | 2 – 8 | n. b. | 0,8 | 50 | 1500 – 1900 | 90 | ||

| Spec, contact resistance | ICE 93+167 | Ohm x cm | 1018 | 1018 | n. b. | 1018 | 1016 | 1014 | 1016 |

| Surface resistance | ICE 93+167 | 1017 | 1016 | 1017 | 1017 | 1014 | 1013 | 1014 | |

| tracking resistance | 53480 | KA 3c | KA 3c | n. b. | KA1 | ||||

| Arc resistance | ASTM 495 | s | > 360 | > 300 | n. b. | > 210 | > 75 | > 30 | > 135 |

| Dielectric strength | 53481 | kV/mm | 40 – 80 | 50 – 80 | 40 – 80 | 50 – 80 | 60 – 90 | 40 – 80 | 50-80 |

* PTFE (polytetrafluoroethylene),

* FEP (perfluoroethylene propylene),

* FEP-HT (Hyflon F),

* PFA (perfluoroalkoxy copolymer),

* ETFE (ethylene tetrafluoroethylene),

* PVDF (polyvinylidene fluoride),

* ECTFE (ethylene chlorotrifluoroethylene)

n.a.: not applicable,

n.b.: not known