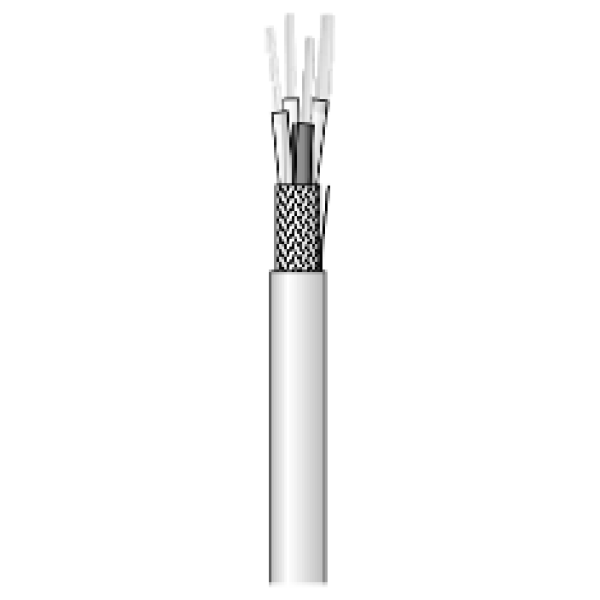

PTFE (polytetrafluoroethylene) insulated cables are often used in applications with very high temperatures or aggressive chemical media. This biocompatible material is also used in medical technology as it is resistant to chemicals and solvents.

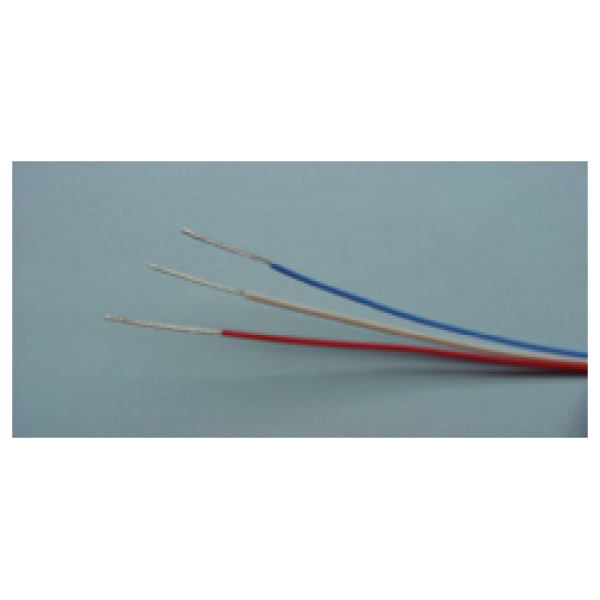

ETFE (ethylene tetrafluoroethylene) has very good mechanical properties, such as high hardness and tear resistance. In addition, the excellent chemical resistance and good electrical and thermal properties allow ETFE-insulated conductors to be used in a wide range of applications.

FEP (fluoroethylene propylene) is a meltable fluoroplastic. It can be extruded and is therefore more flexible than other fluoroplastics. FEP is characterized by its high resistance to temperature, oil and chemicals. In addition, this material is largely biocompatible and is therefore very suitable for applications in medical technology, also because, unlike other fluoroplastics, FEP is easy to sterilize.

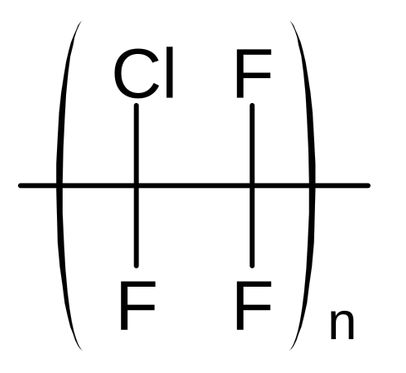

PFA (perfluoroalkoxy) is characterized by good chemical resistance, high operating temperature and good resistance to ageing and weathering. Low frictional resistance and good electrical insulation properties are further particular advantages of this material.