Technical Data

Properties

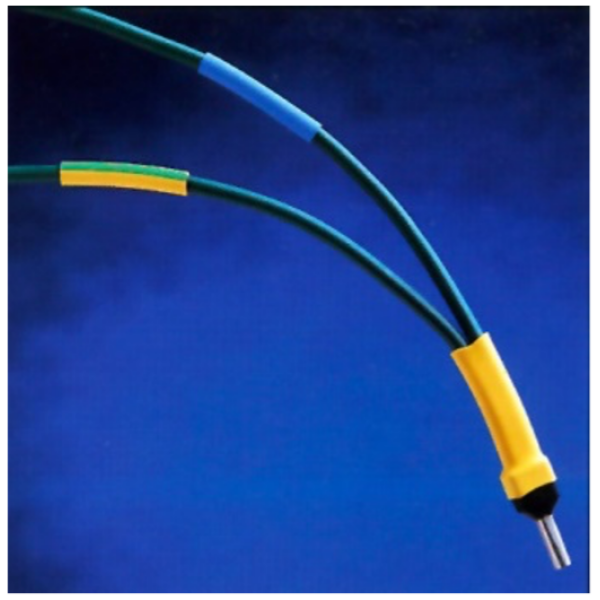

- Cost-effective insulation of wire ends in lacquer-impregnated electric motors of temperature class F

- Material: DuPont™ Mylar®

- Reliable fixation due to shrinkage of 35%.

- Available with inner diameters from 2.50 mm to 65 mm and wall thicknesses from 0.240

- Fast shrinking within 10 seconds.

- Excellent dielectric strength and

- Structure made from a five-ply composite of Dupont™ Mylar® and Nomex®

- The foil si UL approved.

- Resistant to most oils and refrigerants.

- Suitable for applications in temperature class F at

- Continuous temperatures of 155°C.

Outer Lamina:

| Electrical Properties | |||

| Properties of Base Film | Typical Value | Test Condition | Test Method |

| 37.5 HS film (37 μm) | |||

| Dielectric strength [kV] | > 3.5 | ASTM D 149 | |

| Physical Properties | |||

| Properties of Base Film | Typical Value | Test Condition | Test Method |

| 37.5 HS film (37 μm) | |||

| Tensile Strength | |||

| MD (Mpa) TD (Mpa) |

190 | Machine Direction (MD) | ASTM D 882 |

| 260 | Transverse Direction (TD) | ASTM D 882 | |

| Yield [m2/kg] | 19.10 | ||

| Modulus [Mpa] | 2,100 | MD | ASTM D 882 |

| 3,600 | TD | ASTM D 882 | |

| Elongation [%] | 170 | MD | ASTM D 882 |

| 110 | TD | ASTM D 882 | |

| Water Vapour Transmission Rate [g/m2/24 hrs] | 15 | 38°C, 90% Relative Humidity | ASTM F 1249 |

| Oxygen Permeability [cm3/m2/24 hrs] | 75 | Before shrinkage | ASTM D 3985 |

| 30-45 | After shrinkage | ASTM D 3985 | |

| Optical Properties | ||

| Properties of Base Film | Typical Value | Test Method |

| Melt Point | 253-255°C (526-528K) | ASTM D 3148-82 |

Inner Lamina: DuPont™ Nomex® Grade 411

| Electrical Properties | ||||

| Property of Base Material | Material Thickness | Test Condition | Test Method | |

| 0.130 mm | 0.180 mm | |||

| Dielectric Strength [kV/mm] | 12 | 12 | AC Rapid Rise | ASTM D 149 |

| Dielectric Constant | 1.3 | 1.3 | 103 Hz | ASTM D 150 |

| Dissipation Factor | 0.005 | 0.005 | 103 Hz | ASTM D 150 |

| Physical Properties | |||

| Property of Base Material | Typical Value | Test Condition | Test Method |

| Tensile Strength | |||

| MD [N/cm] TD [N/cm] |

17 | 28 | ASTM D 828-60 |

| 9 | 17 | ASTM D 828-60 | |

| Elongation | |||

| MD [%] TD [%] |

3.5 | 3.5 | ASTM D 828-60 |

| 4.8 | 5 | ASTM D 828-60 | |

Item number:

Example: IESMN0100/005/0050

IESMN = master number

0100 = 1.00 mm inner diameter

005 = 0.05 mm wall thickness

0050 = 50 mm inner length (without protrusion)