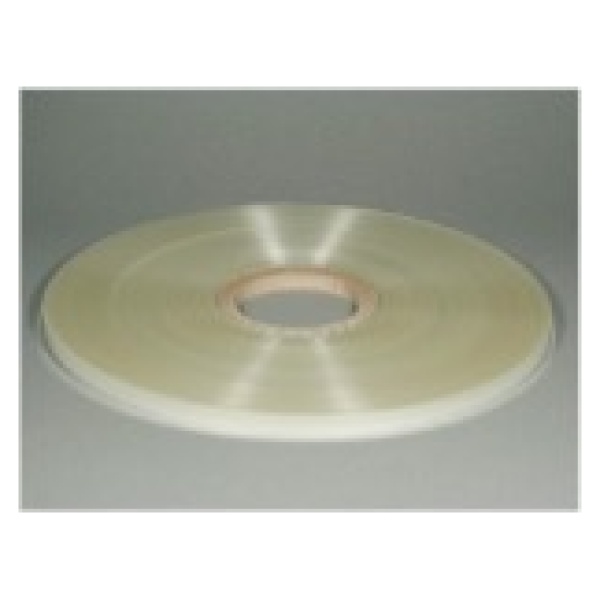

Rolls with individual widths cut to customer specifications

We offer narrow rolls for almost every application. This requires a high level of technical expertise and the use of state-of-the-art production machinery. According to your specifications, our suppliers manufacture rolls from 8 mm width for thicknesses up to 0.18 mm from 6 mm width for thicknesses from 0.19 mm

With a width tolerance of 0.1 mm, they process a wide variety of materials according to your requirements and specifications

For the production of groove insulations, slot closures or intermediate insulations, we also offer the complete production of customised moulded parts. We would be pleased to provide you an offer. Please let us know the required dimensions using the form below

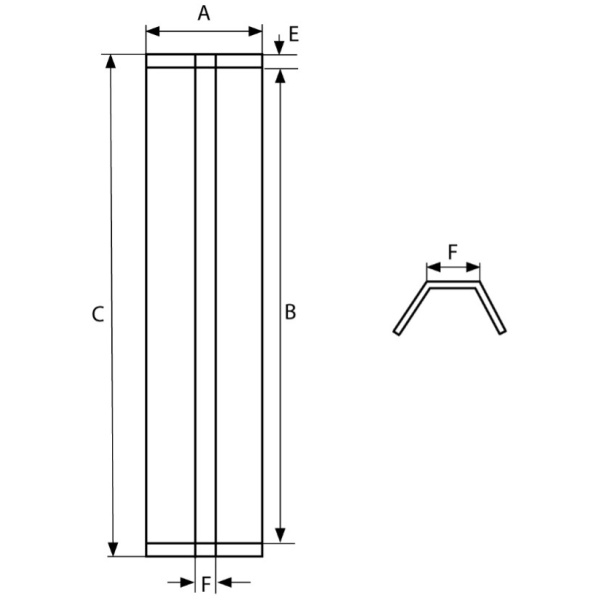

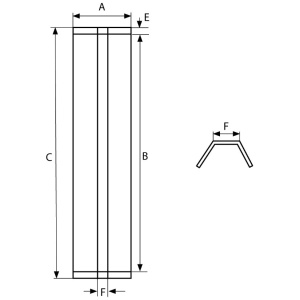

Dimensional drawings for insulating molded parts for electric motors

|

Groove insulations

Material: ………………………………………………………………………………………… Temp. Class: ………………………………………………………………………………. Thickness: ……………………………………………………………………………………. Quantity: …………………………………………………………………………………. Dimensions: A = Overall width: ………………………………………………………….. B = Inside length: ……………………………………………………………… C = Outside length: ……………………………………………………………. D = stretched length: …………………………………………………….. E = Shelf: ………………………………………………………………. F = Rebate (outside): …………………………………………………………….. A x B/C/D ………………………………………………………………. Rebate ………………………………………………………………. Our Art. No. IF…………………………………………………………… Your order no. ……………………………………………………………..

|

|

Slot closures and intermediate insulations

Material: ………………………………………………………………………………………………. Temp. Class: ……………………………………………………………………………………… Thickness: …………………………………………………………………………………………………… Quantity: ……………………………………………………………………………………………….. Dimensions: A = Overall width: ………………………………………………………………. B = Length: ………………………………………………………………. F = Fold (outside): ………………………………………………………………. A x B/ ………………………………………………………………. Fold ………………………………………………………………. Our Art. No. IF……………………………………………………………. Your order no. ………………………………………………………………………………

|