Application examples:

| Industry | Aerospace |

| Electrical insulation | Pressure sensors |

| Adhesive tapes | Speaker cones and voice coils |

| Printed circuit board substrates | Capacitors |

| High-temperature labels | Composite structures |

| Sealing washers in high-speed engines | Suitable for use with lead-free solders |

| Sealing washers in cell phone hinges | |

| Flexible heating elements |

Standard thicknesses and widths:

The standard width of the film is 610 mm – widths up to 1500 mm on request. Standard thicknesses (in µm) – 12, 18, 25, 38, 50, 63, 75, 100, 125, 150, 200. Other thicknesses 250, 300, 500, 750 µm on request. The thickness tolerance is +/- 7 %.

| Minimum purchase quantity 10 kg | 25 µm | 50 µm | 75 µm | 100 µm | 150 µm | 200 µm | 300 µm | 500 µm |

| Surface area [m2] | approx. 300 | approx. 160 | approx. 100 | approx. 80 | approx. 50 | approx. 40 | approx.26 | approx.15 |

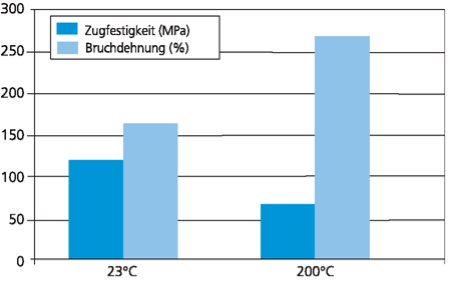

Figure 1: Physical properties at 23 °C and 200 °C for film, 50 µm (ISO 527)

Mechanical properties with different film thicknesses:

| ISO 527 at 23 °C | |||||

| 25 µm | 50 µm | 125 µm | 250 µm | ||

| Tensile strength | MPa | 130 | 120 | 110 | 100 |

| E-modulus | GPa | 3.0 | 2.8 | 2.4 | 2.2 |

| Tear elongation | % | >150 | >150 | >150 | >150 |

Electrical properties with different film thicknesses:

| ATSM D149, 23°C, 1/4″ electrode | |||||

| 25 µm | 50 µm | 125 µm | 250 µm | ||

| Dielectric strength | kV/mm | 270 | 190 | 120 | 70 |

| Breakdown voltage | kV | 6.75 | 9.5 | 15 | 17.5 |

| Test method | Test Condition | Unit | 50 µm | |

| Property | ||||

| E-modulus | ISO 527 | 23 ºC | GPa | 2,8 |

| Tensile strength (at break) | ISO 527 | 23 ºC | M Pa | 120 |

| Tear elongation | ISO 527 | 23 ºC | % | >150 |

| Puncture resistance | Def Stan 81-75 | 23 ºC | kJ/m2 | 26 |

| Tear strength | ISO 6383-1 | 23 ºC | N/m m | 6,7 |

| Shrinkage | TM-VX-84 | 200 ºC | % | <2 |

| Density | ISO 1183 | 23 ºC | kg/dm3 | 1,30 |

| Water absorption (50 % relative humidity) | ISO 62 | 23 ºC, 24h | % | 0,04 |

| Linear coefficient of thermal expansion | ASTM D696 | MD, below Tg | ppm | 47 |

| Dielectric strength | ASTM D149 | 23 ºC, 1/4″ electrode | kV/mm | 190 |

| Contact resistance | ASTM D257 | 100 V, 23 ºC | Ohm cm | 4 x 1016 |

| Dielectric constant | ASTM D150 | 23 ºC, 10 MHz | – | 3,5 |

| Loss factor tan δ | ASTM D150 | 23 ºC, 10 MHz | – | 0,002 |