Copper Shielding Tapes / General Information

Insulated copper tapes for shielding or as high-current conductors for transformers and coils, especially for solar energy and hybrid drive technology (voltage converters).

Advantages of flat copper cables (copper shielding foils)

- Significantly reduced skin effect below 100 kHz, high current carrying capacity

- Flat copper cables can be wound very tightly at high tensile forces. This effectively prevents vibration of the bobbin (e.g. 50 Hz hum) and dissipates the resulting heat loss.

- Low inductive reactance from 5 Hz to 50 kHz Very good (loss) heat to power ratio due to good conductivity and low skin effect. Significantly higher power density compared to wire-wound coils.

- Very fast shielding between input and output winding, as only one winding is required (DIN EN 61558; IEC 60950 Safety of information technology equipment)

- Lower capacitive component than with round wire windings and excellent quality (audio applications)

- As interlayer shielding Prevention of interturn short circuits between primary and secondary winding

- For the production of induction loops (ring circuits, ring loop systems) for hearing aid systems

- Insulated flat copper wire can also be used for busbars

Further information

- Copper foil thickness range: 35 – 300 µm (other thicknesses on request)

- Conductor cross-sections from approx. 0.1 mm² to approx. 45 mm² possible

- Electrolytic copper E-Cu 58 is used, soft with a spec. resistance of 0.017 Ohm x mm² /m. A current carrying capacity of 2-2.5 A per mm² area can be roughly calculated (with moderate self-heating).

- Also available with 10µm copper foil on request – super-flat design!

- On request, we can also supply bare copper foil, cut to the required width.

- Alternatively, aluminum on request

- Delivery form: roll, 5 – 300 mm wide (depending on copper thickness and design)

- Application: EMC protection, insulation according to DIN VDE 551, EN60742, as current winding in power transformers

- Also possible with double and triple insulation

- Also available with PEN film for class F

- for even better heat dissipation with Kapton® MT insulation

- Also with two conductors in parallel for more complex winding designs

- Also available with three-layer insulation (three separable layers; if required, with insulating adhesive tape that has passed the Mandrel test from EN 61558)

- other designs required? Just ask!

Copper Shielding Tapes/ Options of Executions

| Sketch | Structure | Master number | ||||

| Material | ||||||

| polyester | Nomex® | Kapton® | PEN | |||

|

Insulated on one side, with overhang | KA38181 | KA38281 | KA38381 | KA38481 | Simple insulation |

|

Insulated on both sides with protrusion and with soldering gap | KA38191 | KA38291 | KA38391 | KA38491 | Simple insulation |

|

Insulated on both sides, with overhang | KA38182 | KA38282 | KA38382 | KA38482 | Simple insulation |

|

Insulated on both sides, with soldering gap | KA38190 | KA38290 | KA38390 | KA38490 | Simple insulation |

|

Double insulated on both sides, with soldering gap | KA38193 | KA38293 | KA38393 | KA38493 | Double insulation |

|

Insulated on both sides without protrusion and without soldering gap | KA38192 | KA38292 | KA38392 | KA38492 | Simple insulation |

|

KA38194 | KA38294 | KA38394 | KA38494 | Double insulation | |

|

Structure: soldering gap, copper, insulation |

Data sheets are available on request. |

||||

| Copper thicknesses

35/50/100/150/200/250 and 300 µm, other Insulation foils Polyester 25/36/50/75/100/190 µm Widths From 6 mm to approx. 250 mm Delivery form As rolls, standard length 100 m |

Item number Example: KA38181/150/050/010.0 KA38181 0 Master number 150 = Copper thickness in µm 50 = Foil thickness in µm 010.0 = Width in mmFurther order details Poss. insulation width (for protrusion) Poss. width of solder gap, possibly fiddling |

Further optional executions for copper shielding tapes

Parallel, individually insulated power cables on a double-sided adhesive carrier. For example, for the simultaneous installation of DC supply cables in furniture with LED lighting. Very easy installation due to self-adhesive equipment of the supply lines, extremely low overall height.

Insulated copper tapes series CMC 38xxx as shield winding

In addition to the desired inductive coupling, (unwanted) capacitive transmission of higher-frequency interference signals can also occur in transformers and coils. To avoid this, a shield made of copper foil can be inserted between the windings of a transformer. This shielding winding acts like a Faraday cage for the electric field, but hardly affects the magnetic energy transmission. Capacitive coupling can be drastically reduced in this way. The use of insulated copper foils as a shield winding on ring transformers (EMC shield) is particularly well known. The shield winding is usually only connected on one side and is connected to earth. Another use for insulated copper foils is shield windings, which are used as additional insulation protection. In the event of an insulation fault, there is no breakdown from the primary to the secondary side of the transformer. Instead, the insulation fault is absorbed by the intervening shield winding. A fuse element connected to the shielding can then trigger a fuse in the event of an insulation fault, for example. Laminates made of copper foils (aluminum foils) and Films are also used as current conductors in transformers (insulated flat copper conductors). The main advantage here is the high surface area of the profiled copper in relation to the cross-sectional area. At high currents and high frequencies, the conductor surface is primarily responsible for electrical conduction due to the displacement of charge carriers (skin effect). In addition, copper strips can be wound tightly onto the winding carrier with high tensile forces. This avoids vibrations and increases the power density. In addition, heat dissipation is improved by the close contact, which can be further supported by thermally conductive insulation.

Advantages of insulated copper tapes

- Prevent capacitive coupling

- Increase safety as a shield between primary and secondary winding

- Have a large surface area (replacement for stranded wire)

- Can be used up to class H (polyester, PEN, Kapton®)

- High current carrying capacity, high current carrying capacity (e.g. TIG welding)

- Compliance with clearance and creepage distances due to insulation

- Easy wire connection by soldering thanks to soldering gap

- Insulated on one and both sides, also multi-layer insulation

- Available in a wide range of widths and material thicknesses

Correct handling of CMC 38xxx copper shielding tapes in production

One of the most important aspects when handling the reels is protecting the sensitive edges. With versions such as CMC 38190, for example, the very thin but stress-resistant insulation can easily be damaged by misplacement. As a result, only insufficient dielectric strength is achieved.

For power transformers: Up to 1000µm copper foil

Flat copper conductors up to 1,500 µm Especially in solar technology (converters for solar power) and for charging electric vehicles, very high currents are converted into high voltages and vice versa. Today, the solid copper conductors required for the current side are mainly manufactured using wires in the form of insulated flat copper strips. When using such insulated strips, it should be noted that the dielectric strength changes significantly depending on temperature and, above all, frequency. In particular, pulsed edges with a rise time of a few nanoseconds stress the insulation material. Partial discharges must be avoided. CMC Klebetechnik offers – customized – insulated copper tapes made of electrolytic soft copper up to 1000µm copper thickness. The above information and our technical application advice, whether verbal, in writing or by means of tests, are provided to the best of our knowledge, but are non-binding. This advice does not exempt you from checking our current advice, in particular our data sheets and technical information as well as our products with regard to their suitability for the intended processes and purposes

Tape with multiple conductors along the running meter

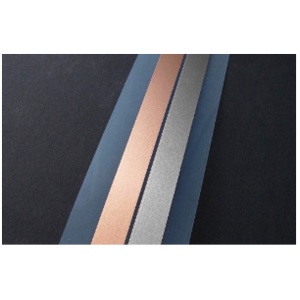

For some constructions or power supply lines, it is advantageous to have several insulated flat copper conductors next to each other on a carrier foil. The carrier foil “bundles” the individual conductors into one cable. A combination of a copper conductor and a tinned copper conductor is available for DC power supplies – e.g. for LED lighting. Reverse polarity is therefore a thing of the past (see picture).

DC supply cable with “reverse polarity protection” You can receive up to three insulated flat copper cables next to each other. Please enquire if you have a specific requirement!

Current carrying capacity of single conductors

Ambient temperature 30°C (self-heating approx. 30°C)

| Wire cross-section | 0.75mm² | 1.00mm² | 1.5mm² |

| Current carrying capacity max. duration | 6A | 10A | 13A |

Ambient temperature 40°C (self-heating approx. 30°C)

| Wire cross-section | 0.75mm² | 1.00mm² | 1.5mm² |

| Current carrying capacity max. duration | 4,9A | 8,2A | 10,7A |

Ambient temperature 50°C (self-heating approx. 30°C)

| Wire cross-section | 0.75mm² | 1.00mm² | 1.5mm² |

| Current carrying capacity max. duration | 3,5A | 5,8A | 7,5A |